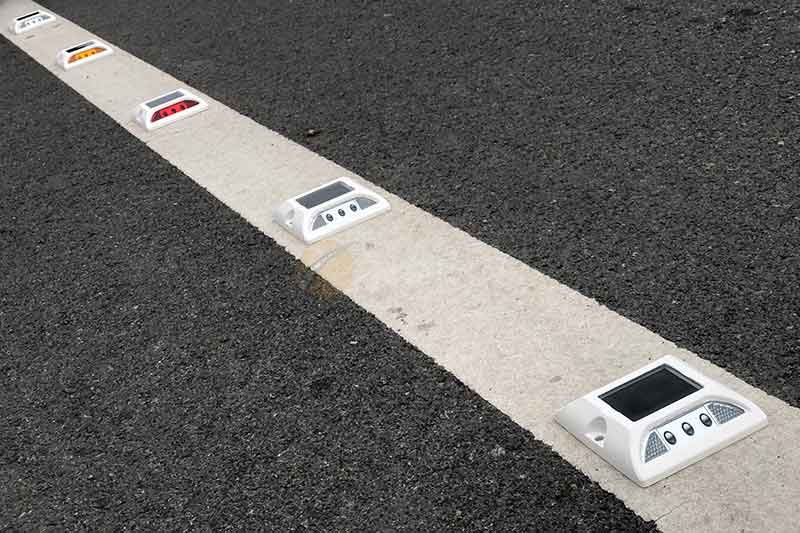

Solar LED road studs are charged by solar energy and automatically emit light at night and when there is insufficient light in rainy and foggy days, which can guide vehicles to drive correctly and effectively ensure traffic safety. Solar LED road studs are not only easy to install and use, but also conducive to energy saving, so they are widely used.

Low compression performance is the fatal flaw of solar led road studs, so how to improve the compression performance of solar road studs? Usually we use the following three methods:

First, The exposed solar panels are made of PC bulletproof material, which enhances the pressure resistance of electronic components.

Second, use IC control as much as possible to reduce the volume of electronic circuits and reduce the pressure on some electronic components.

Third, some reinforcing ribs are designed on the shell of led road studs to share the pressure on the electronic components.

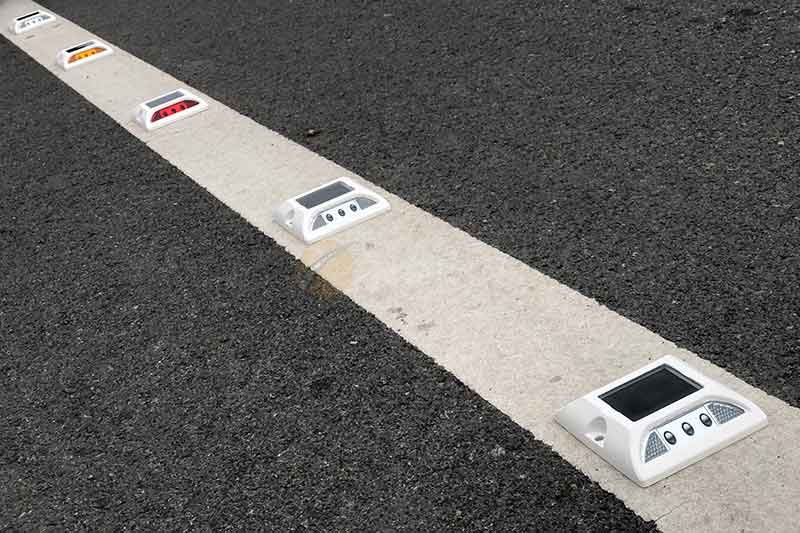

1. The solar led road stud has high luminous brightness. The reflective brightness of ordinary

reflective road stud is only 300-400 mCD, while the luminous brightness of solar road studs can reach 2000 MCD, which is 6-7 times that of the former. Such high-intensity light can penetrate the rain and fog at night and guide the driver safely and effectively.

2. the solar road stud can actively emit light and give a dynamic alarm. The led road stud flashes at a certain frequency at night, and the dynamic warning function is very strong. Active lighting can not only avoid rain and fog interference to a greater extent, but also free the driver's sight from relying on the car's lighting, with a longer visual distance and better results. This is an advantage that ordinary reflective road stud do not have.

(1) The shell is not compressive. The rolling standard for road studs of the Ministry of Communications is more than 16 tons, but in fact, the standard value of most road studs is not up to the standard value.

(2) The reflective sheet falls off. Due to technical problems, most of the reflectors are ultrasonically welded to the shell, and the reflector will fall off and crack when impacted.

(3) The reflective sheet is not wear-resistant. The road is full of sand. Under the tire, sand often wears off the reflective surface of the road stud. The pure plastic reflector does not reduce friction, and the brightness is reduced by 50% in three months. The reflection loss effect can be solved by adding a transparent wear-resistant layer on the surface.