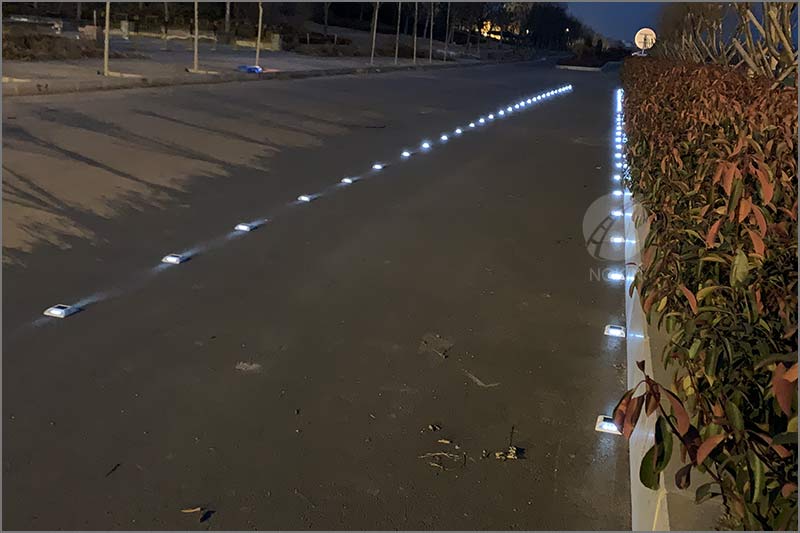

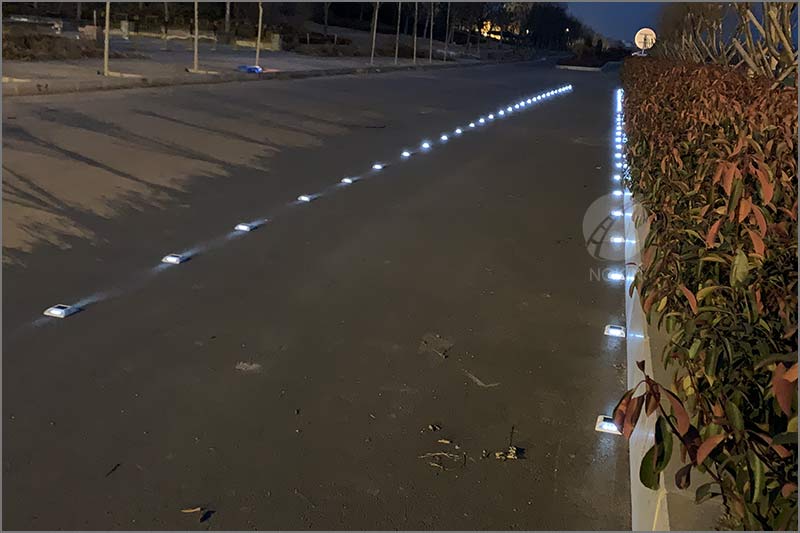

Solar led road stud is a new type of traffic safety device, which can emit light at night and in dim light. Through light, solar led road studs can illuminate road markings and remind drivers to pay attention to the edge of the road. Solar led road stud has a good effect on traffic safety.

In addition,

solar led road studs are known for their durability, compression resistance and impact resistance. Qualified solar led road stud products can be used all year round without maintenance and replacement. However, some solar road studs will have problems in compressive capacity because of poor quality. The led road studs may be crushed, or the shell and inner core may be separated.

This is because the solar led road stud structure is unreasonable. There are two kinds of unreasonable solar road stud structure: hollow inside and wrong solar road stud with pin foot structure.

First case: although some

solar led road stud products are aluminum shell, they are easy to be damaged. Don't just look at the aluminum shell solar road stud, think aluminum solar road stud is more compressive, in fact, these products are hollow under the solar panel. No pressure at all.

The second case: the upper and lower parts of solar led road stud products are connected with several screws. At present, most of the solar led road studs with pin feet adopt this structure. When the solar led road stud is installed on the road surface and fixed with glue, it is only fixed and bonded to the lower part of the solar led road stud, and the upper part is only fixed to the lower part by a few small screws.