The road stud, which is also called raised pavement marker, we refer here is mainly used in highways, and it is a traffic safety facility. the road stud is mainly installed between the road lines or double yellow lines, and it can warn the drivers to drive on their right way by its retro-reflection.°

The normal sizes of the road stud are 100mm*100mm*20mm, and it won’t higher than 25mm. There are several kinds of reflectors, such as reflective panel, reflective bead, led, reflective transfer file.

It usually uses the epoxy resin to install the road stud.

According to its material:

According to its function:

According to its reflective surface:

The cast aluminum road stud, plastic road stud, ceramic road stud and amber road stud can be classified into the normal road stud. I will introduce the road studs in detail according to their functions:

1. Cast aluminium road stud

The cast aluminium road stud can be classified into the whole cast aluminium road stud and the road stud only with cast aluminium shell. The whole cast aluminium road stud is made by metal material, which has strong pressure resistance, and it is usually used inside the double yellow lines. There is filler inside the road stud only with cast aluminium shell, and the cost of this kind is lower than the whole cast aluminium road stud, and it the pressure resistance of it is also not good as that.

2. Plastic road stud

The plastic road stud can also be divided in to the whole plastic road stud and the road stud with plastic shell. The whole plastic road stud refers to the road stud that made by plastic, or ABS, AS+ fiberglass, which has strong pressure resistance. The road stud with plastic shell only has a plastic shell and there is filler inside the road stud, and the cost is lower than that one, so is the pressure resistance.

3. Ceramic road stud

The ceramic road stud is made by cement ceramics, and it shapes round, which is always used in previous time. For it is easy to broken, this kind of road stud is not recommended.

4. Amber road stud

The amber road stud is made by glass, and it is used in previous time. For it is difficult to install, it is also not recommended to be used.

5. Road stud with reflectors

The reflector is 21 or 43 reflective beads.

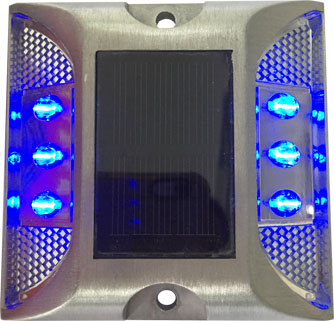

Using the solar panel as charging equipment and battery or capacitance as storage equipment, the solar road stud uses the led or combines passive luminance products of road stud to give out light. Composed by retro-reflective material, shell, solar panel, led, and controller, the solar road stud always equips with the facility of visual induction, and it usually works together with the traffic lines, the visual effect of which is better than that of the normal road stud.

Using the solar panel as charging equipment and battery or capacitance as storage equipment, the solar road stud uses the led or combines passive luminance products of road stud to give out light. Composed by retro-reflective material, shell, solar panel, led, and controller, the solar road stud always equips with the facility of visual induction, and it usually works together with the traffic lines, the visual effect of which is better than that of the normal road stud.

Characteristics of the Solar Road Stud

1. High brightness:

The reflective brightness of the ordinary reflective stud is only 300-400MCD, but the brightness of the solar road stud can be over 2000MCD, which is 6 to 7 times of the former one, and the high brightness can penetrate rain or fog at night and guide the way effectively for the drivers.

2. Flashing synchronically and giving warnings initiatively:

The solar road stud can flash in a certain frequency at night, and the visual of people are more sensitive to changes, so the warning function of the solar road stud is quite strong. Giving out light initiatively can not only avoid interruptions of rain and fog to the greatest extent, but make the drivers get rid of the reliance of light of cars, which will make the visual distance longer and greater. The solar road stud plays key role in rainy or foggy days and it does more in the aspect of eliminating security risks.

Classification of the Solar Road Stud

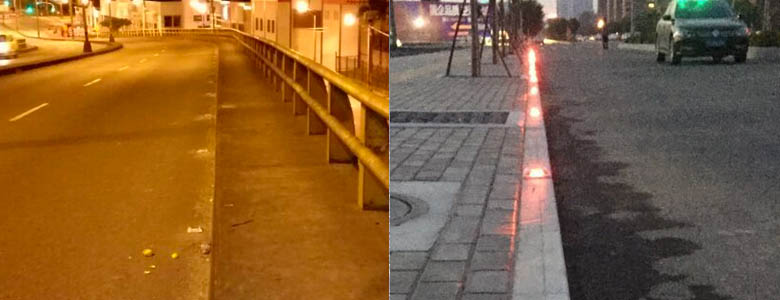

The solar road studs can be divided into embedded type and raised type according to the difference of installation place.

Generally, the former will be used in central lines, and the latter will be used sidelines. That is because the solar road studs that installed in the central lines should have strong pressure resistance, and in order to solve this problem, the workers should have to embed the studs into the roads, and only leave 5 mm on the road surface. And the pressure resistance of the solar road studs installed in the sidelines does not require that high as the studs installed in the central lines, so it can work effectively even the raised type is used.

The solar road studs can also be divided into two types according to the difference of the storage devices, and one uses the capacitance, and the other uses the battery. For these two types, the life span of the former one can be 5 to 7 years, and that of the latter one is 1 to 3 years.

For the embedded solar road studs do more harm to road surface, and the cost of capacitance solar road studs are relatively high, so the raised types are widely used nowadays.

Performance Indicators of the Solar Road Stud

When research the basic characteristics of any kind of solar road stud, the following aspects should be considered.

1. Pressure Resistance

If the solar road stud cannot work under a certain extent of pressure, it will be out of work after several times crush or crash. So the compression resistance should be the most basic condition for the solar road stud. For the solar road stud is a electronic product, it is not that easy to make the road stud has strong pressure resistance. Thus the pressure resistance of the solar road stud is lower than the ordinary road stud.

There are several methods to increase the pressure resistance of solar road stud: 1). Use the PC bullet resistant material to make the solar panel outside to increase the pressure resistance of the electronic part of the road stud; 2). Use the IC control to decrease the volume of electronic circuit; 3. Put the reinforcing ribs on the shell to share the pressure on the electronic part.

2. Sealing property

The water will permeate into the solar road stud if it is not sealed tightly, which will cause short circuit, so the sealing property of the solar road stud should be good.

Several methods are provided to increase the sealing property of the solar road stud:

1). Separation design. Adopted separation design of the led lampshade and the circuit board inside the road stud, and even the led lampshade is out of work, there will be no water permeating inside the solar road stud.

2). Using the strong neutral adhesive to ensure that the solar panel, led lampshade and the shell of road stud can bond tightly, and there is no gap between them.

3. Brightness

Solar road stud has one special characteristic when compared with common road stud, and that is, it must auto luminescence. The transportation sector has relative standard for this index, which is 2,000MCD.

4. Stability

Life span of the battery: Another factor that influences the life span of the solar road stud is the using time of battery, so it is quite important to choose a battery with good performance. Now there are two kinds of batteries to choose, and one battery whose capacity would reduce to 50% after 500 times charge-and-discharge and the other is the battery whose capacity would reduce to 79% after 1,000 times charge-and-discharge.

The using life of a battery should be long enough, and it must be working effectively in a wide range of temperature interval. The material inside a battery is chemical substances, and it cannot work in the environment which is too hot or too cold. So, the working temperature range should be abided with requirements of actual using environment. The requirement of related standard made by transportation sector for this index is that the solar road stud should work in the temperature between -10℃ to 50℃. Actually, the working temperature of solar road stud may out of this range, so the battery with reliable quality and excellent performance need to be chosen to make the solar road stud.

Electronic circuit: The design principle of simple and effective should be followed. One more circuit will increase the possibility of malfunction. The electronic components should also be chosen strictly, for the whole system will be out of work if one electronic component is broken.

Welding: The welding of the solar road stud should be firm. For it is crashed or shocked everyday, a little loose of the welding spot will cause the loose of break off of the circuit, the high-quality welding gun and soldering should be chosen to ensure that the wielding spot is firm and can work long enough in severe environment.

Solar panel: The solar panel can absorb solar energy and transform it into electric energy, and this can be the first link of the whole working system of the solar road stud. The efficiency of the solar panel determines the efficiency of the solar road stud. The single crystal silicon solar panel is widely used nowadays, for it has high photoelectric conversion efficiency, which can be about 14%, to ensure the energy providing when the solar road stud is working. In addition, the solar panel must be high hardness and wear-resisting. For the solar road stud will resist crash and shock everyday, if it is not hard enough, the solar panel will be destroyed and influence the conversion efficiency of the solar panel.

5. Matching Performance of Battery

The rated capacity of the battery should meet the needs of 72 hours’ illuminating, if the battery is put in the standard testing condition for 8 hours. Even if the solar illumination is less than 1,000LX, the rated capacity of the battery should make road stud work normally for 12 hours after 8 hours’ charge. One thing should be noted, if the matching performance of battery is not that good, it will be lack of power in wet weather, which may cause the un-illuminate of solar road stud. If this condition happens, the solar road stud will out of particle value. This is also the limitation of capacitive solar road stud. If being put under the standard testing condition for 8 hours, the rated capacity capacitor can only make the solar road stud work for 12 to 14 hours, that is to say, the capacitive solar road stud is strict with its actual working environment, which should not only have enough sunshine, but should not work in continuous rainy weathers.

Tunnel cable road stud is a traffic safety facility which is more advanced than solar road stud. It regards solar panel or alternating current as input source, and control the working condition (Blinking or normally on) of the road stud through the controller. And the tunnel cable road stud works much more effectively than the solar road stud. The road studs are connected by wires. And the control diameter of every group of controllers can be around 1000 meters.

Tunnel cable road stud is a traffic safety facility which is more advanced than solar road stud. It regards solar panel or alternating current as input source, and control the working condition (Blinking or normally on) of the road stud through the controller. And the tunnel cable road stud works much more effectively than the solar road stud. The road studs are connected by wires. And the control diameter of every group of controllers can be around 1000 meters.

The intelligent wireless road stud can receive the wireless signal given out by the controllers and work through the signal. There is no wire between the road studs, which is much more convenient for installation. However, the sending and receiving of wireless signal are a difficulty.

With the development and mature or the technology of road stud producing, there must be more kinds of road studs are made for clients to choose.

It is not complex to install the road studs, but there are some details, which play key role to guarantee the quality and service time of the road stud, should be noticed.

With the wide application of road studs in the construction of urban roads of our country, the quality and using life of road studs has been paid more attention. However, in the practical application, the road studs are damaged or the using time is reduced because of abnormal installation.

Common problems appear in the installation process of road studs:

1. Being installed in the traffic lines.

The traffic lines, which are attached to the surface of road, are drawn by resin material, and its connection with the road surface is in a certain limitation. If the road studs are installed in the traffic lines, the impulsive force received by road studs would pass to the traffic lines, which may cause the fall apart of road studs with road, which would also do harm to the traffic lines.

2. The road stud is installed in uneven place.

If the installation place of road stud is uneven, it will cause non-uniform load of road studs directly, and the press on the road studs will focus on the raised and sink parts of them. The road studs will be broken if they are crushed by large-tonnage vehicles.

3. The road stud is not installed in clean space.

The degree of soundness of road studs relies on the close connection of road stud, glue and the surface of road. If the installation space is not clean, the dust will reduce the adhesive strength of glue, which may cause the insecure of road studs. And they will fall apart when external force crashes them.

4. Too much glue or too little glue.

If the glue is not enough, the soundness of adhesion will be reduced, however, the superfluous glue will leak out around the road stud with too much glue on it, and the glue may contact with the reflectors, which may have influence on the reflecting light of them.

5. Nonuniform glue on road studs.

When install the road stud, the glue should not only be used in right quantity, but should be paint uniformly. In this way, every part of the road stud will full-stressed to avoid being broken because of nonuniformation.

6. Epoxy resin adhesive is not made in suitable temperature.

Epoxy resin adhesive is the two-component adhesive, and the glue and hardener should be mixed with a certain percentage, and it will be effective only when they are mixed evenly. However, the epoxy resin adhesive will be condensed in cold winter days, which is not easy to mix evenly, so it should be heated after it soft enough before using the epoxy resin adhesive.

7. Not hold the road studs in the right way.

When holding a road stud, you should take the two sides without reflectors. If you do not behave this way, the glue may influence the reflecting light of the reflectors.

8. The installation hole site is shallow or thin.

This tip is for cast aluminum road stud with a foot. The cast aluminum road stud with a foot has good shock resistance and pressure resistance, and it can be used for long time. But if the hole site is too shallow or too thin, the underside of road stud cannot connect with the road surface fully, which may influence the soundness of the road stud.

9. Not enough solidification time after installation

After the installation of the road studs, it needs some time to solidification to connect the surface of road with the road stud tightly. In my opinion, the solidification time should reach 4 hours. But in real life, the isolation facilities will be removed 2 hours after the installation. And this is not good for the road stud. If it is crushed or crashed by cars, it may out of shape, but in some severe cases the road stud would fall apart with road.

Low Shock Resistance of the Reflector

The key problem of the raised pavement markers sold in the market has low shock resistance, and more than 80% products have this problem. Most of the reflectors are welded into the body of the road stud by ultrasonic, and the reflectors will fall apart with the road stud body when shocked. If the road stud is emerged in rain, the reflector on it will be fade.

Testing method: do shock test on the road stud reflector, and draw out the white panel, then throw down a steel ball weighing 1kg vertical to the surface of the reflector, and emerge it into water, and then test the brightness of the reflector. If there is not water penetration, the brightness won’t decrease.

Bad Pressure Resistance of the Shell

The standard of pressure resistance of the road stud is over 16 tons, however, most of the road studs in the markets cannot meet the standard.

Fast Reflective Brightness Decay of the Reflector

The sand on the ground may wear and tear the reflective surface by the rolling of wheels, and the plastic reflector cannot anti-friction, and the brightness of the road stud will decay about 50% after 3 months’ working and lose the reflective effect. And this problem can be solved by a transparent abrasion resistance layer on its surface.

Copyright © 2011-2018 by NOKIN All Rights Reserved.